Digital transformation in oil and gas can improve efficiency and productivity in an industry that largely relies on traditional, and often outdated technologies. Not only do these older technologies put workers at risk, but they can also lead to unplanned downtime, which can be costly and hard to recover from.

Enhancing workflows with new solutions can make it easier for companies in the oil and gas industry to fuel high-level decision-making, reduce risks, and improve operational efficiency overall. However, digital transformation is easier said than done. How do organizations in the oil and gas industry implement meaningful technological change?

In this blog post, we’ll guide you through the essential steps to conducting digital transformation in oil and gas in a way that’s approachable and realistic for any company.

What is Digital Transformation in the Oil and Gas Industry?

Digital transformation in the oil and gas industry helps companies use emerging technologies to streamline operations and work more efficiently. For an industry that has been around for decades, this tech upgrade is majorly needed in so many companies to upgrade outdated systems.

From AI to data analytics and predictive maintenance solutions, modern tools enable teams to tackle traditional challenges while reducing costs, minimizing environmental impact, and helping teams work safely. Digital transformation in oil and gas is allowing companies to automate processes, improve supply chain management, and use technologies like IoT sensors to monitor critical operations.

Key Challenges Driving Digital Transformation in the Oil and Gas Industry

Research shows that 70% of companies that have run digitization projects haven’t moved past the pilot stage. For the oil and gas industry to evolve, it needs to rise to the occasion and tackle some of its core challenges, such as:

- Aging infrastructure: Outdated equipment needs constant maintenance and can lead to lower productivity

- Safety: High-stakes environments require predictive solutions and 24/7 monitoring

- Fluctuation prices: Profit margins on oil are tight, so a cost-efficient operation is critical

- Environmental requirements: Strict regulations require greener solutions

- Data overload: There’s a lot of data to monitor in oil and gas, but outdated processes limit the ability to analyze and act on it

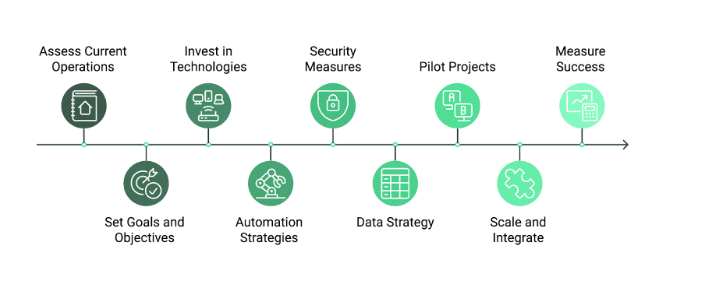

9 Steps to Implementing Digital Transformation in the Oil and Gas Industry

Digital transformation in the oil and gas industry can seem like a gigantic task, which might be why so many companies are hesitant to start. However, with a well-structured and carefully paced plan, there’s no reason why your company can’t achieve results. US upstream companies that have prioritized digital transformation saw a 7% increase in net income between 2014 and 2023, despite a drop in oil prices.

Below, we’ll look at nine basic steps to take to successfully implement digital transformation initiatives to improve efficiency and modernize your operations.

1. Start with a clear vision

Before diving straight into getting new tech, you first need to assess your current business operations and sort through your data and processes to understand where digital transformation can be the most effective. Start by identifying gaps, problems, and areas for improvement by examining your legacy system and seeing where technologies can help update processes.

2. Set Clear Goals and Objectives

After you get a good picture of where your company is currently at, define what you hope to achieve through digital transformation. This can be anything from reducing downtime to cutting costs or improving safety. Set clear, measurable goals to help guide your digital transformation strategy at all times.

3. Invest in the Right Technologies

You don’t need to invest in every piece of new technology. Instead, focus on solutions tailored to the oil and gas industry to help you bridge any gaps you identified. Technology that enables you to centralize data to respond to changing global events or political instabilities is essential to any operation. Some other solutions that could be a good fit include:

- Artificial intelligence (AI): From analyzing data to helping predict machinery maintenance, AI goes a long way in oil and gas

- Cloud platforms: Store and access data securely and remotely, while using a platform that’s easy to scale when needed

- Enable mobility: Since the COVID-19 pandemic, there’s been an increasing need for mobile tools that offer remote access and real-time data to keep everyone connected

- IoT devices: Sensors and other IoT devices can give you instant updates on machinery status and also help with predictive maintenance

- Blockchain: In supply chain management, blockchain technology for oil and gas can improve transparency, traceability, and reduce fraud, making it easier to track and verify orders

4. Create Automation Strategies

Automation is key to reducing manual workloads, so it’s important to identify repetitive tasks early on, like data entry or equipment monitoring. Automating processes with AI will free up your team to focus on higher-value tasks and will allow you to better understand which technologies you should prioritize.

5. Strengthen Security Measures

New technologies, unfortunately, come with new risks. Cyber security becomes a big concern when handling sensitive data over the cloud and other connected devices. As part of your implementation process, create new robust security protocols to protect sensitive information and stay compliant with oil and gas industry standards.

6. Develop a Data Strategy

Your data strategy goes hand-in-hand with your security strategy, so it’s important to decide how you want to collect, store, and analyze data to get the most important insights. As an industry that relies on quick decision-making, having access to accurate and reliable data can significantly boost productivity and help you avoid unnecessary downtime. For example, collecting data through speech with technology like aiOla is non-disruptive to existing digital workflows and can go a long way in gathering important quickly and efficiently.

7. Plan and Implement Pilot Projects

Start implementing new solutions with small pilot projects. This way, you can test new technologies and processes in one specific workflow to understand what works and what still needs improvement. It also ensures your team isn’t bombarded with learning too many new systems all at once.

8. Scale and Integrate Across Operations

After testing pilot projects and seeing that they work as you intended them to, it’s time to roll out the changes across your entire operation. New systems and tools should be integrated with existing systems, or even replace legacy systems that may no longer be relevant.

9. Measure Success and the ROI of Your Digital Transformation

Finally, you want to make sure you’re tracking the results of your digital transformation. Go back to the start of your plan and examine whether the results you’ve gotten have allowed you to meet the initial goals you set. Has downtime decreased? Have you reduced costs? Measuring results and ROI will allow you to directly see how your efforts have led to tangible benefits and help you refine your strategy to make more improvements down the line.

Digital Transformation Starts By Choosing the Right Technology

When it comes down to it, the technology you choose is going to make the biggest impact in your digital transformation journey. Of course, assessing gaps, setting goals, and planning implementation are also important, but choosing the right solution will get you closer to your goals and get you the results you want.

Implementing speech AI technology like aiOla is an easy choice. The technology can help you automate critical workflows and make frontline workers safer and more productive while collecting important data through speech to inform business decisions. If that wasn’t enough, since the platform is entirely based on natural speech, there’s almost no learning curve involved and it’s quick to adopt and integrate, making successful digital transformation an attainable reality.

Schedule a demo with an expert today to see how aiOla can boost digital transformation in the oil and gas industry.